Products

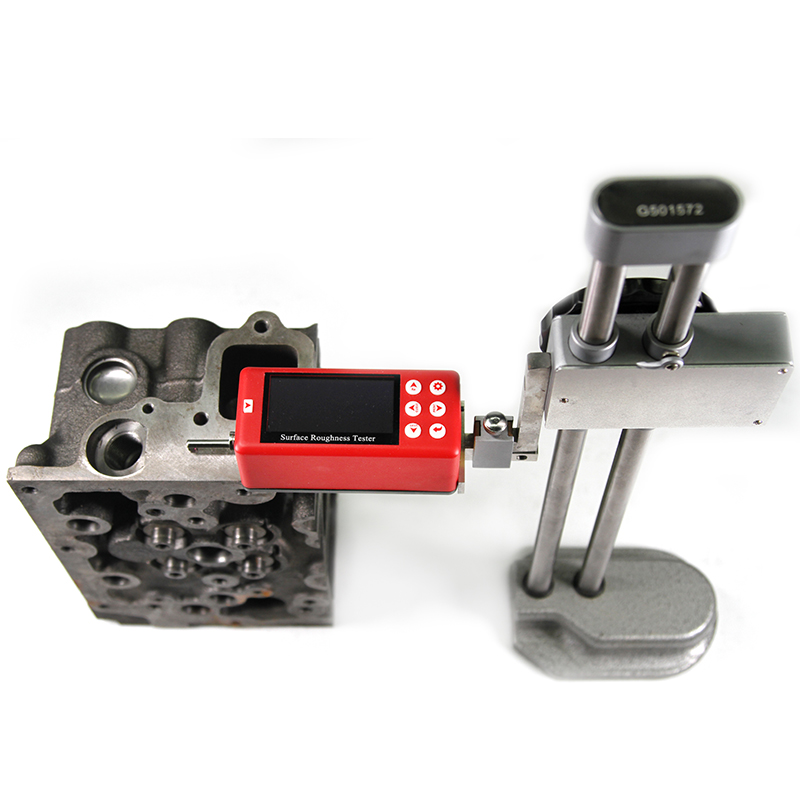

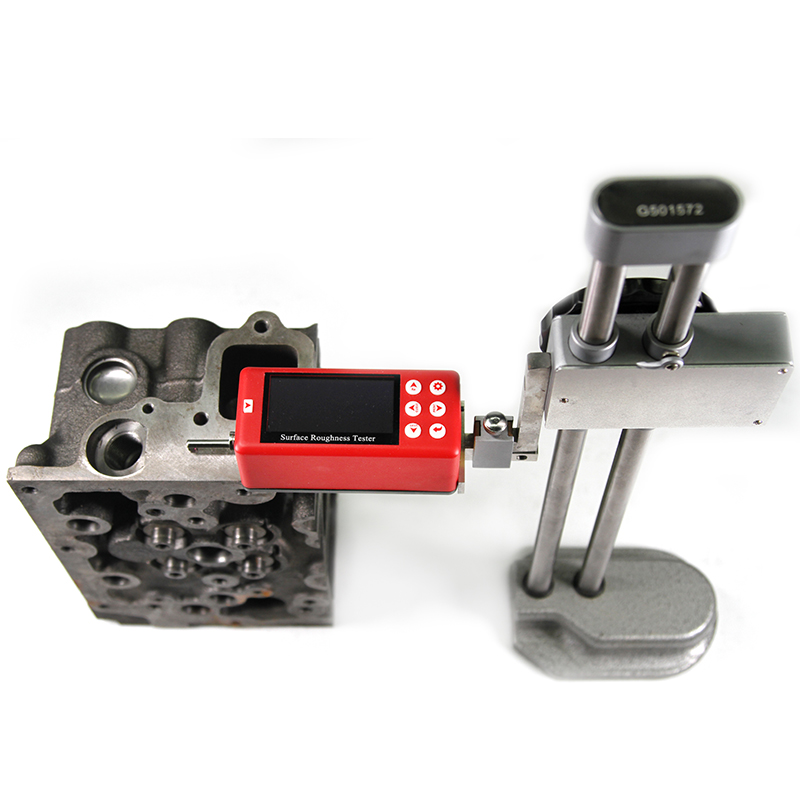

Height support pillar

The height support pillar of Mitech portable surface roughness tester MR200, the optional configuration for this instrument, mainly used for supporting the instrument, make the position between it and the tested workpiece relatively parallel and stable, effectively contact with special position like groove or small hole and so on to realize the surface roughness measurement. It enlarged the application range of the surface roughness tester. It should pay special attention to avoid the damage to the sensor caused by faulty operation when using the height gauge pillar. When the sensor is close to the workpiece surface, it is necessary to carefully observe the stylus position on the screen. It would be OK to make the needle stay at the position of the zero graduation line on the display. When the Ra value of the measured surface is small, it is recommended to use the measurement platform and use the remote control to start the measurement to reduce the impact on the measurement result caused by the external environment. Except the standard sensor, the others sensors like curved surface sensor, deep groove sensor, small-hole sensor need to work with height gauge pillar together.

×

郵箱反饋

如您在和我公司的交往中遇到問題,可通過以下方式和我們取得聯(lián)系!

您也可以撥打我們客戶服務熱線:400-0600-280

MITECH CO. LTD

TEL :

86-10-58859527

008613810243516

ADD:

E-506, 1# of ShangDi East Road, Haidian District, Beijing, China

Email:

mvip@mitech-ndt.com